Electric Atlas Learns to Find Fallen Objects, Adjust Tasks Without Stopping, and Work with Unfamiliar Parts — A Step Toward Autonomous Industrial Assistants

Boston Dynamics has released a demo showcasing the latest version of its all-electric humanoid robot, Atlas, designed to operate in dynamic industrial environments. The video demonstrates Atlas moving motor parts by estimating their position and shape, while adapting to unexpected situations like a dropped object.

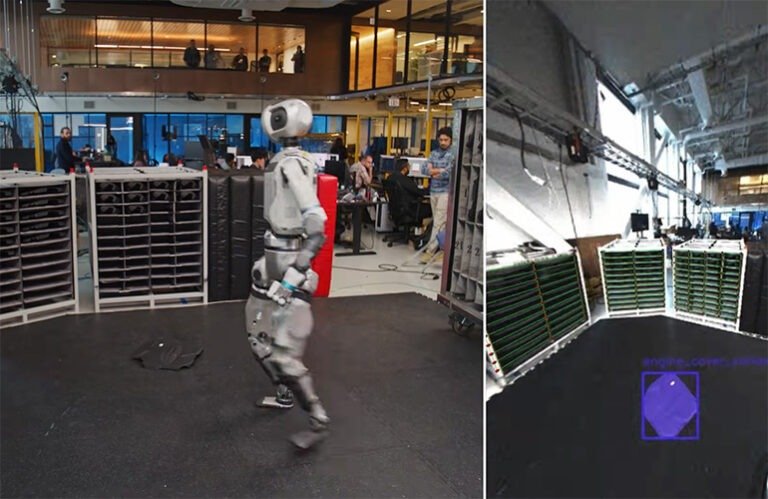

At one point, an engineer intentionally drops an engine cover on the floor. Atlas pauses, turns its head, scans the room, locates the part with its cameras, analyzes its geometry, and carefully places it back in its proper place.

“The search in this segment was manually triggered,” said Scott Koendersma, head of research at Boston Dynamics. “But in real-world scenarios, the robot will be able to automatically detect failures using the same vision algorithms.”

To recognize objects, Atlas uses a pose estimation model that compares a 3D digital model of a part (CAD) with images from monochrome cameras. Trained on synthetic data, the system works “from scratch” with new objects simply by loading their digital models. The robot generates up to 200 hypotheses about the object’s position, selects the most accurate one using a scoring neural network, and adjusts its actions accordingly.

The main difference from industrial robots of the 1990s is mobility. Earlier robots were fixed to the floor and relied on manually calibrated 2D cameras for a specific area. Atlas, however, creates and constantly updates a 3D map of its environment. This allows it to work in changing settings, such as warehouses or workshops, where parts often move around.

The demo combines AI-driven computer vision with traditional task management software. Unlike previous motion-capture videos showing fluid dance movements, Atlas’s motions here appear more deliberate. As Boston Dynamics CTO Aaron Sanders noted at the Robotics Summit 2025, the current challenge is speeding up data processing. In the demo, Atlas occasionally “freezes” to analyze the scene, but future improvements in code optimization and multimodal training will reduce these pauses.

“The race is on for AI that enables robots to adapt, learn, and make real-time decisions,” Boston Dynamics said. The company envisions Atlas being deployed in logistics and manufacturing, where 70% of tasks are still done manually due to a lack of flexible autonomous systems.