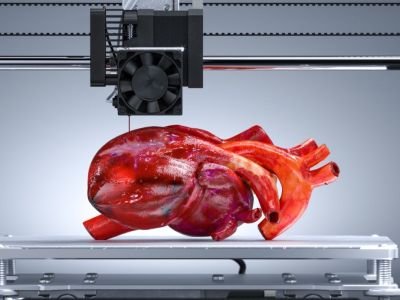

Researchers at the California Institute of Technology have unveiled a groundbreaking technique called Deep Tissue In Vivo Sound Printing (DISP) — a non-invasive method for 3D printing biological tissues, sensors, and even drug-delivery implants directly inside the body without the need for surgery.

Deep Tissue In Vivo Sound Printing

At the core of this innovation is the use of ultrasound to solidify a special injectable bioink. While the bioink remains in a liquid state at body temperature, it solidifies into desired structures under targeted ultrasound exposure. The process is monitored in real time using specialized molecules, and any excess ink is safely broken down by the body.

Unlike traditional light-based 3D printing, which is limited in depth and tissue penetration, ultrasound can reach up to 20 cm deep without causing tissue damage. In laboratory tests, the DISP system successfully printed structures inside the stomachs of rabbits and bladders of mice. By incorporating conductive nanoparticles, researchers also managed to print biosensors and implants capable of controlled drug release.

Challenges and Future Development

Despite promising results, DISP technology is still in its early stages. One major challenge is printing on moving organs like the heart and lungs, where constant motion changes tissue geometry. To address this, researchers are exploring the use of AI algorithms to adjust ultrasound parameters in real time, allowing the printing process to adapt dynamically to organ movement.

The development of DISP opens up exciting possibilities for non-invasive medical treatments, personalized implants, and real-time tissue repair, potentially transforming modern healthcare.