Researchers have successfully developed a novel and compact wind energy generator that foregoes traditional rotating turbines. Instead, this innovative device converts the aerodynamic vibrations of a flexible plate, induced by wind, directly into electricity. The key principle behind this technology is flutter – the self-sustaining, oscillatory motion of a thin polymer plate coated with a piezoelectric material as wind flows past it.

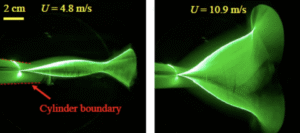

In operation, as wind passes over a specifically shaped cylinder to which the polymer plate is attached, it causes the plate to flutter, similar to a flag waving. This fluttering motion generates mechanical vibrations, which are then converted into electrical current by the piezoelectric coating. The behavior of the plate is dependent on wind speed. At lower speeds, the movement is weak and aperiodic. However, as the wind speed increases, the system reaches a state of resonance. In this resonance mode, the plate’s oscillation frequency synchronizes with the frequency at which vortices are shed from the cylinder (a phenomenon known as vortex shedding). This synchronization leads to high-amplitude, periodic oscillations, dramatically increasing the deformation of the piezoelectric material and consequently boosting electricity generation.

The scientists behind this development have achieved a significant breakthrough, increasing the efficiency of their turbine-less system by 100 to 1000 times. This improvement has resulted in a power output sufficient to continuously illuminate 20 LEDs. Furthermore, when the generator was connected to a circuit incorporating a rectifier and an energy storage device, it was able to briefly power up to 40 LEDs using the accumulated charge.

This new approach to wind energy harvesting opens up exciting possibilities for the creation of autonomous sensors and low-power electronic devices. A significant advantage of this technology is its potential for low manufacturing costs due to the absence of complex moving parts like turbines and gears. While the current prototype demonstrates promising results, the engineers are actively working on further optimizing the system’s efficiency to unlock its full potential for broader applications.